Effective Quality Management

Raw Material Inspection

Suppliers Risk Management

We exclusively partner with suppliers who uphold high standards of ethical conduct, social responsibility, and environmental protection. All metals and raw gemstones require verified testing reports and purchase contracts to ensure they are safe, ethically sourced, and compliant before being used in our finished jewelry products.

Each Process Has Standard Operating Instructions

Based on the ISO 9001 systems, we create and keep updating our own operating instructions to produce jewelry of even better quality. For every stage in production, we set up a specific testing round to ensure absolute quality. This is where Pideajewelry stands out as a different jewelry manufacturing company.

8 way to plating quality inspection processes

Salt Spray Test

Vibration Abrasion Test

Sulfur Dioxide Test

Artificial Sweat Test

UV Test

High Temperature Test

Rubbing Test

Hardness Test

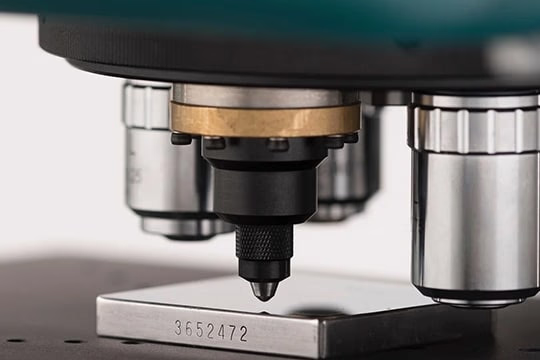

Finish Inspection for Every Product

According to product types and technics used, later inspections cover different items focusing on the possible defections. Every piece of jewelry go through the process.

Design/Structural Inspection

- Design Accuracy: Size deviations from the original design sketch are kept within 5%, with a maximum tolerance of 1.5mm, unless specified otherwise.

- Mechanical Integrity: All mechanical components (clasps, locks, etc.) are crafted to match the confirmed CAD design exactly.

- Structural Durability: We rigorously test structural strength to eliminate risks of cracking, misshaping, or gemstone dislodgement.

- Material Fidelity: Gemstones and metal parts adhere strictly to the design file, matching cut, shape, quantity, finishes, and overall appearance. Colors align with standard color charts for consistency.

Appearance Inspection

- Welding Precision: All welding points are seamlessly executed, leaving no visible marks or imperfections.

- Surface Quality: The entire jewelry surface is pristine, free from blisters, spots, or cracks.

- Finish Consistency: Surface finishes (polished, brushed, sandblasted, hammered, etc.) match the confirmed samples exactly.

- Plating Excellence: Plating colors fall within the specified tolerance range, with even, consistent coating free from bubbling, peeling, scratches, or stains.

- Gemstone Integrity: All stones are expertly polished, free of cracks or scratches, with cuts and thickness adhering to industry standards.

- Adhesive Quality: Glue is robust and durable, applied without overflow or discoloration, ensuring a clean and lasting bond.

Transparency and Traceability

Transparent material sources

Trace Every Single Material Batch

Need More Details?

Curious about our jewelry or want to learn more about our quality? We’re here to help.