PVD Coated Jewelry

As a leading PVD jewelry manufacturer, we combine advanced coating technology with your stylish designs, offering enhanced durability and a luxurious finish that stands up to daily wear and tear.

PVD Coated Jewelry Just Slays!

In jewelry, PVD means Physical Vapor Deposition, it’s a technique especially for stainless steel jewelry.

Its resistance to rust, tarnish, and corrosion makes it an excellent choice for everyday wear. The versatility of stainless steel allows for a wide range of designs, from sleek and minimalist to intricate and bold, catering to diverse tastes.

Its low maintenance and enduring shine ensure that stainless steel jewelry remains a top choice for those seeking both style and longevity in their accessories.

3

With our honest material and plating technique, the PVD jewelry we offer can last at least 2-3 years. Proper care and maintenance can significantly extend its lifespan.

0.03-0.08

18K

PVD gold jewelry involves a real gold layer. We use 18K gold as our gold layer for its outstanding performance in enhancing the wear resistance and longevity, though it is much expensive.

| 10K | 14K | 18K | 22K | 24K | |

| % Pure Gold | 41.70% | 58.30% | 75% | 91.60% | 99.90% |

| Hallmark | 375 | 583 | 750 | 916 | 999 |

| Popularity | Least Popular | Most Popular | Most Popular | Popular but expensive | Less accessible |

Pro Tips:

* Custom plating thickness is available for orders meeting the prescribed quantity. Contact us to discuss further if you need a thickness greater than 0.08 microns.

* For general, everyday use, 304 stainless steel is often sufficient and more cost-effective.

* Be aware that the hardness of stainless steel can pose challenges in creating extremely delicate designs.

* 18K gold-plated stainless steel jewelry is an ideal choice if you’re seeking hypoallergenic and waterproof pieces at an affordable rate.

* Like what’s indicated by its name, stainless steel jewelry does not tarnish easily and does not turn green.

The Magic Behind PVD:Stainless Steel Jewelry Made Waterproof

Discover the transformative power of PVD coating in stainless steel jewelry. This advanced coating not only adds a luxurious finish but also ensures long-lasting protection against wear and environmental elements. Explore how PVD makes stainless steel jewelry both stylish and waterproof.

Stainless Steel Material

TiN Layer (Titanium Nitride)

The Gold Layer

Popular PVD Plating Colors

14K Gold

18K Gold

Rose Gold

Rhodium Plated

Black Plated

PVD Coating for Long-lasting Pieces

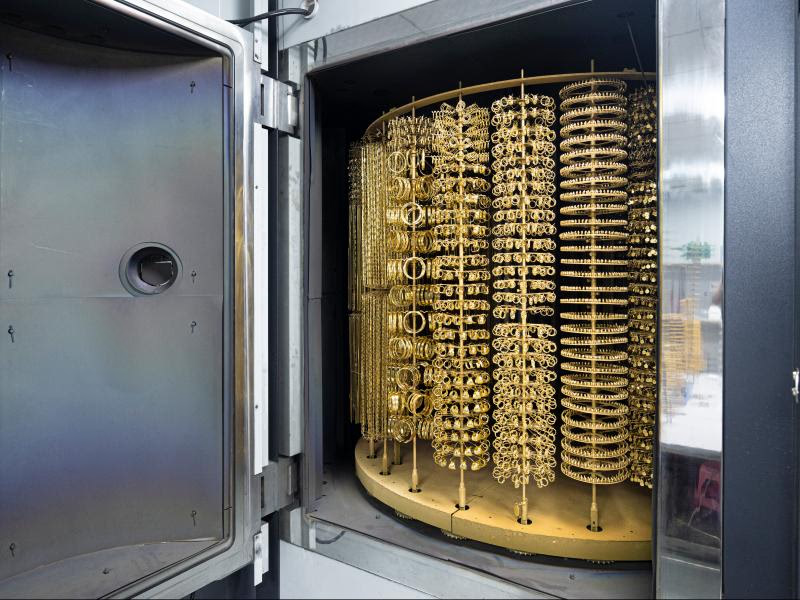

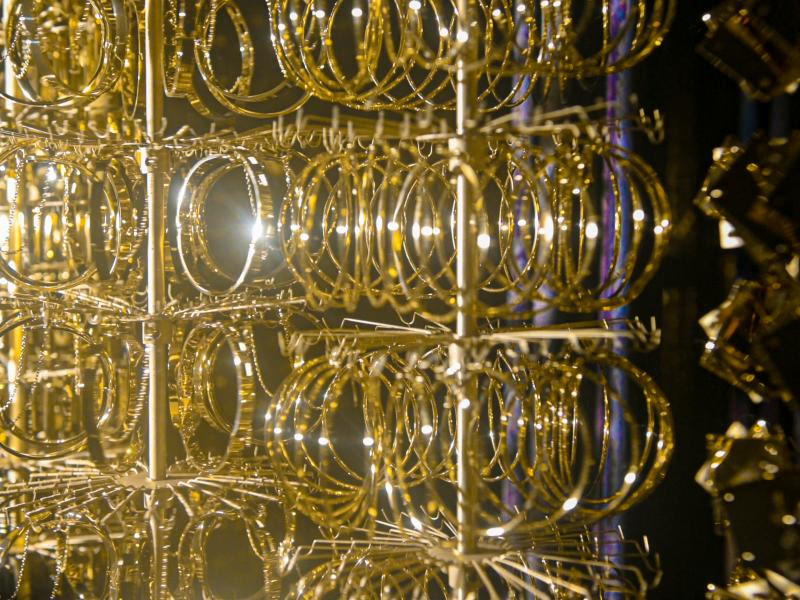

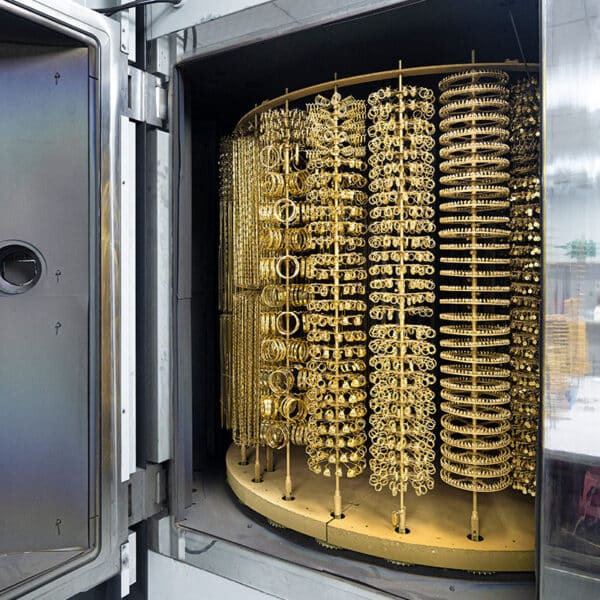

The Physical Vapor Deposition (PVD) process at Pidea involves vaporizing metal compounds and depositing them onto the jewelry surface, creating a durable, premium finish. Our PVD coating enhances the aesthetic allure of your pieces while providing exceptional protection against wear, corrosion, and tarnishing, ensuring lasting brilliance.

Step 1: Jewelry Uploading

Step 2: Cleaning and Drying

Step 3: Vacuum Sealing

Step 4: Vaporized Coating

Step 5: Unloading & QC

Step 6: Finished Jewelry

Send us your design and we’ll make it happen.

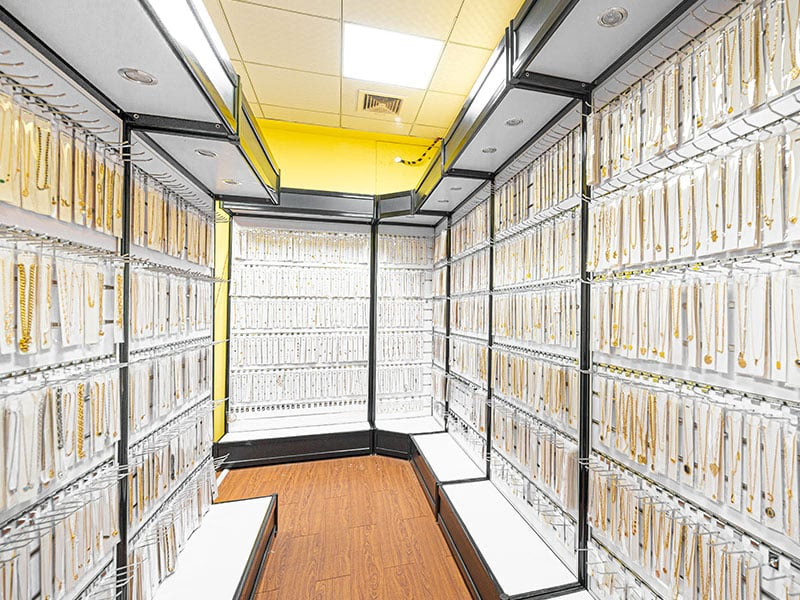

Creative Flair of PVD Jewelry

Whether you prefer sleek minimalism, striking contrasts, or futuristic designs, PVD coating delivers exceptional protection and durability, ensuring your jewelry remains stunning and long-lasting.

Add Personalized Touches

Make it Bold & Chunky

Spiritual Symbols

Shine with Natural Stones

More than Just Jewelry: A Partnership

01

Innovative Design Collaboration

We assist in developing and inspiring your new jewelry collection through AI designs, trending concepts, and refinement of your initial ideas. Let us transform your seed designs into a standout collection.

02

Excellence in Design and Production

03

Ongoing Marketing Support

We’re with you through the marketing phase, helping determine optimal times for replenishment and product launches. Together, we’ll strategize responses to slow sales and manage inventory effectively.

04

Your Partner in Entrepreneurship

The Magic Behind PVD:Stainless Steel Jewelry Made Waterproof

Design-Driven Crafting Processes

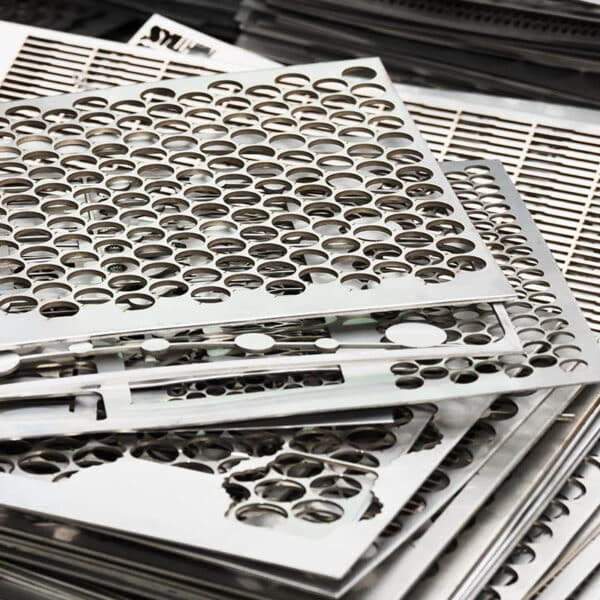

Flat Pieces with Hollow Sections

Casting from Making A Mold

Casting enables intricate and elaborate designs, capturing fine details with exceptional precision. The process involves crafting a detailed mold and pouring molten stainless steel into it. Expert mold-making and precise metal pouring ensure every design element is accurately replicated, delivering flawless results.

Designs with Simple Textures on Surface

Precision Laser Cutting

Our laser cutting technology precisely profiles grooves and etches intricate patterns onto stainless steel jewelry. This method delivers exceptional accuracy and efficiency, perfect for creating detailed, flat designs while minimizing material waste.

Designs with Simple Textures on Surface

Texturing Surfaces with Stamping

Simple surface textures are crafted through stamping or punching at Pidea. We soften the stainless steel and use a stamping mold with precise, controlled force to imprint the desired texture. This method ensures uniform, accurate surface patterns, elevating both the visual allure and tactile quality of the jewelry.

Crafting Perfect Pieces

Hypoallergenic as a Second Skin

Premium Surgical-Grade Stainless Steel

We craft our jewelry exclusively with authentic 316 stainless steel, renowned for its superior durability and hypoallergenic properties. This ensures our pieces are not only corrosion-resistant and built to last but also safe and comfortable for those with sensitive skin, offering worry-free wear.

Nickel Release Compliance with CA Prop 65 Standards

Our commitment to safety drives us to meet the stringent CA Prop 65 standards for nickel release. By adhering to these rigorous regulations, we minimize the risk of allergic reactions, delivering a safer, more eco-conscious jewelry line that prioritizes both quality and consumer well-being.

100% Recyclable - Supporting a Circular Economy

Stainless steel stands out as the most recyclable metal, making it a prime choice for businesses dedicated to sustainability.

Each piece of stainless steel jewelry can be recycled indefinitely without compromising quality, promoting a circular economy that prioritizes resource reuse over waste. This recyclability resonates with the rising consumer demand for eco-friendly products that support long-term environmental sustainability.

By opting for stainless steel, you deliver durable, high-quality jewelry while meeting the growing market need for environmentally responsible choices.

Sustainable Manufacturing That Leaves No Trace

At Pidea, we recognize that sustainability is more than a trend—it’s a vital priority in today’s market. We are dedicated to crafting stainless steel jewelry that adheres to the highest environmental standards.

Here’s why stainless steel is the ideal choice for businesses aiming to embrace eco-conscious values and meet the growing demand for sustainable products:

By selecting Pidea’s stainless steel jewelry, you’re choosing pieces that embody exceptional craftsmanship while resonating with the values of today’s eco-conscious consumers.

This dedication to sustainability sets your business apart in a competitive market, meeting the growing demand for environmentally responsible jewelry that combines style with purpose.

Erasing Our Environmental Impact

Green Materials

Zero Waste

Zero Chemical Emission

Get Solutions For Your Business Success

With Pidea, you’re not just choosing a supplier—you’re partnering with a team committed to your success. Let us bring your jewelry visions to life with our comprehensive, tailored solutions.

Perfect Jewelry Sample Every Time

Private Label Jewelry